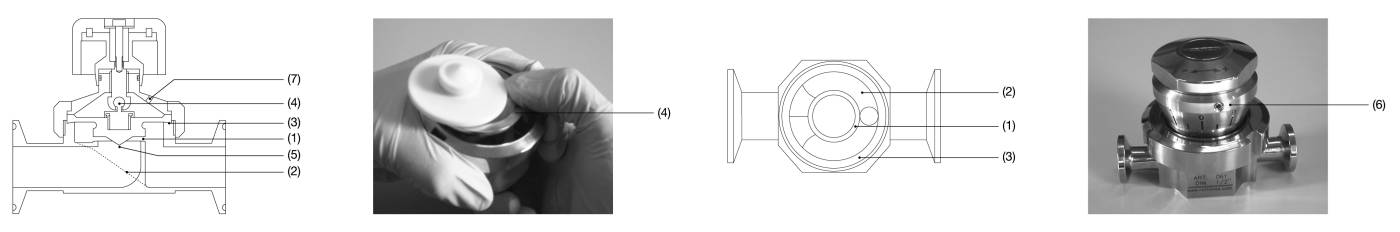

The opening and closing movements do not detect the areas which are away from the shutter’s contact surface, which however, is inclined and it allows the draining of the fluid outwards during the support movement and the tightness of the diaphragm on the work table shutting surface (1). The internal chute allows the valve’s chamber to easily empty itself even during horizontal use (2).

The inverse taper of the tightness surface in correlation with the diaphragm’s surface sustain allows for concentrated tightness on the internal edge, which is in contact with the product, it is secured by a strong and optimal compression, and it is performed by the external roller (3).

In order to guarantee the maximum quality, the central body is totally machine-manufactured, using welded Tri-Clamp connections, available with internal finishing under 0.4 Ra. The diaphragm is manufactured in PTFE, which is appropriately connected to the AISI316L traction-compression systems, therefore there is no possibility of by-passing, and it has a spherical conformation which makes the replacing maneuver easy (4).

The runner in the shutter makes any eventual needs to regulate the fluid more precise (5).

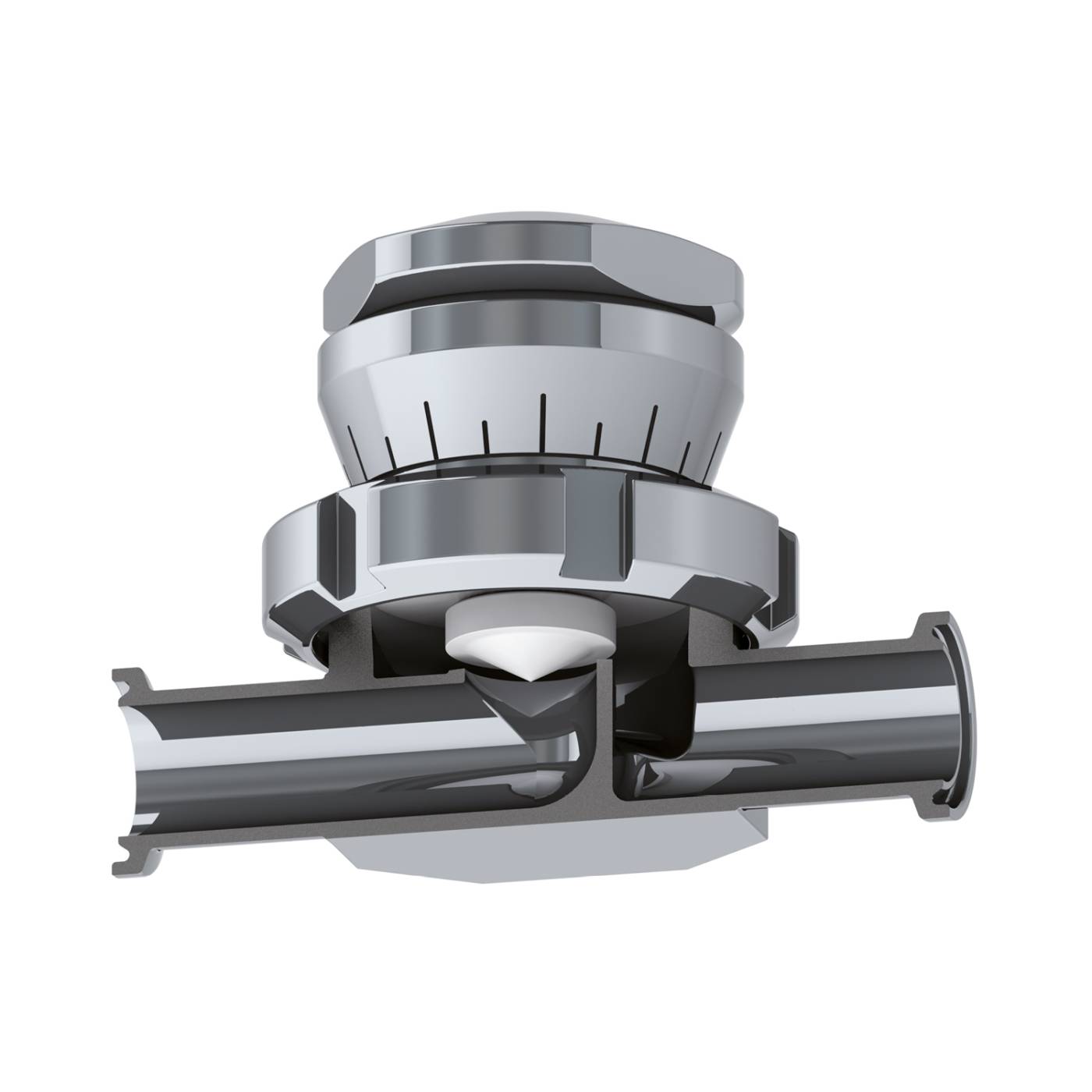

The manual control of the valve is carried out through a PTFE handle. For precision regulation purposes, a manual, self-locking actuator is available (Type H); it includes 80 different positions, as well as a position indicator, which is available only for 1/2” and 3/4” (6).

The hole on the head-frame valve allows the external display of any possible cracks on the diaphragm (7).