TOOLS FOR PROFESSIONAL BIOPHARM ENGINEERS

For over forty years the flat membrane diaphragm valve has ruled the pharmaceutical and biotech landscape and remains virtually unchanged. However, in today’s ultra-competitive and highly regulated landscape the question has to be asked: are the tools from forty years ago still relevant? Rattiinox has been developing and manufacturing a wide range of aseptic valves and custom components for the global pharmaceutical, biotech sector since 1970. In that time Rattiinox has engineered several unique valve designs. Most recently in 2010 Rattiinox introduced the most advanced aseptic radial diaphragm valve along with the widest range of standard valve configurations – 100 types that span the valve range from ½” to 4”.

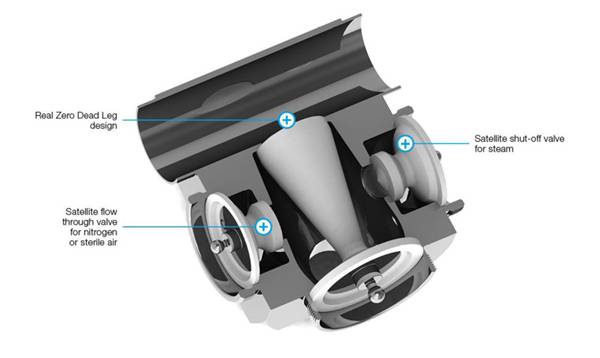

In doing so, Rattiinox has developed an entire range of valves dedicated to point of use and sampling off of a main pipe. The CAD “Valve on Pipe” range of products covers pipe and valves ranging from ½” to 4” main pipe and ½” through 2” valves integrated into the pipe. The valve port can be either located coaxial to the main pipe in the case of take-off and sampling applications or tangential in those cases where the pipe needs to be fully drained. Additionally, the “Valve on Pipe” can be equipped with an integral steam valve for SIP downstream line before takeoff.

For more critical working conditions (sterile applications) the assembly can be provided with a second satellite valve to allow drying with Nitrogen and holding the downstream pipeline under sterile conditions.

Most recently Rattiinox has also engineered a version of the “Valve on Pipe” that can be installed in a vertical pipe. The CAD valves are lightweight and very compact.

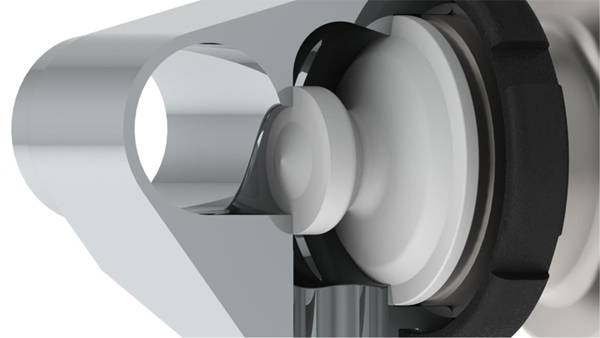

There are two key factors that contribute to the Rattiinox CAD valve being the superior choice for these and other high purity applications. The first is the valve design itself. The right angle geometry of the radial diaphragm valve lends itself to economically producing a wide range of valve styles and porting without sacrificing ease of cleanability and sterilization and always with maintaining a zero dead-leg to the process. The second key feature, which is unique to the CAD valve, is the precision machined PTFE diaphragm. The CAD valve is the only diaphragm valve, either flat membrane or radial, that has been engineered specifically to use a solid PTFE diaphragm. The performance benefits are significant.

Customers using the Rattiinox CAD valves fitted with PTFE diaphragms enjoy unprecedented reliability and length of service. Even in applications that regularly see steam, aggressive cleaning and high temperatures above 135°C as well the CAD valves outperform the competition. Vacuum conditions while diaphragms are hot, is a real world condition to be avoided at all costs. The Rattiinox CAD valve is unaffected under these conditions. Not having to wait while valves cool in order to protect the diaphragms saves valuable processing time.