Introduction of ISO 9001

Our company has recently achieved a significant milestone by implementing the ISO 9001 quality management standard. This certification reflects our commitment to continuously improving our processes, meeting customer expectations, and adhering to the highest quality standards across all operations. ISO 9001 has guided us in refining our management systems and production technologies, ensuring a more efficient and traceable production environment.

Enhancements Aligned with ISO 9001

As part of our ISO 9001 implementation, we have focused on integrating advanced technologies to meet the standard’s requirements for quality control, process efficiency, and traceability. These innovations have been introduced with the goal of improving product quality, minimizing risks, and ensuring compliance with international standards.

MES System Integration with Quality Management

Our company has been utilizing a Manufacturing Execution System (MES) to monitor production processes in real time. With the introduction of ISO 9001, we have further integrated this system with a comprehensive quality management module. This integration ensures that quality checks are performed at every stage of production, and all data related to production and quality control is stored and analyzed systematically. This allows us to immediately identify and rectify discrepancies, ensuring that all products meet the highest standards.

This system integration supports a culture of continuous improvement, a core tenet of ISO 9001, by providing real-time insights and enabling quick decision-making to maintain optimal product quality.

Automated Warehouses for Enhanced Traceability

To further align with ISO 9001’s focus on risk management and traceability, we have implemented automated warehouses for storing finished and semi-finished products. These systems allow us to maintain detailed, accurate records of all product movements, ensuring full traceability throughout the supply chain. This capability is essential for complying with ISO 9001, as it allows us to document every step of the production and storage process, offering transparency and reducing potential for errors.

State-of-the-Art Ultrasonic Washing Machine

As part of our commitment to meeting ISO 9001 standards for product cleanliness and quality, we have installed a cutting-edge ultrasonic washing machine. This machine operates in a closed chamber, ensuring high-performance cleaning that removes even the smallest contaminants. The controlled environment guarantees consistent results, which are critical to meeting the stringent quality standards required under ISO 9001. This technology ensures that our products are meticulously cleaned before reaching the final stages of production or shipment.

Future Technology Enhancements

Looking forward, we are introducing Automated Guided Vehicles (AGVs) and a dedicated electronic raw material warehouse system. These technologies, which will be operative in few weeks, will be implemented to further strengthen the reliability of our production system and optimize processes. The AGVs will automate the transport of materials throughout the production facility, ensuring traceability and minimizing human error. Similarly, the raw material warehouse system will provide full visibility of material movements, contributing to even higher standards of traceability and efficiency.

Benefits of ISO 9001 Implementation

The integration of these advanced technologies, in line with ISO 9001, has already delivered several tangible benefits for our company:

1. Improved Product Quality: The enhanced MES system, combined with real-time quality control, ensures that all products meet or exceed ISO 9001 standards before they are shipped to customers. This reduces defects and enhances customer satisfaction.

2. Enhanced Traceability: Our automated storage systems and future AGVs ensure full traceability of raw materials and products throughout the production process. This is essential for complying with ISO 9001’s focus on risk management.

3. Operational Efficiency: The automation of material handling and storage, including the upcoming AGV and raw material warehouse systems, streamlines our processes and reduces the risk of human error.

4. Continuous Improvement: By integrating quality management with our MES system and preparing for the implementation of AGVs and automated storage, we are setting the foundation for ongoing improvements in both efficiency and quality.

Conclusion

The introduction of ISO 9001 has been a transformative step for our company, driving us to refine our processes and adopt advanced technologies that enhance product quality, traceability, and operational efficiency. By continuously investing in these systems, including future technologies such as AGVs and raw material warehousing, we are ensuring that our operations meet the highest international standards, aligning with the principles of ISO 9001.

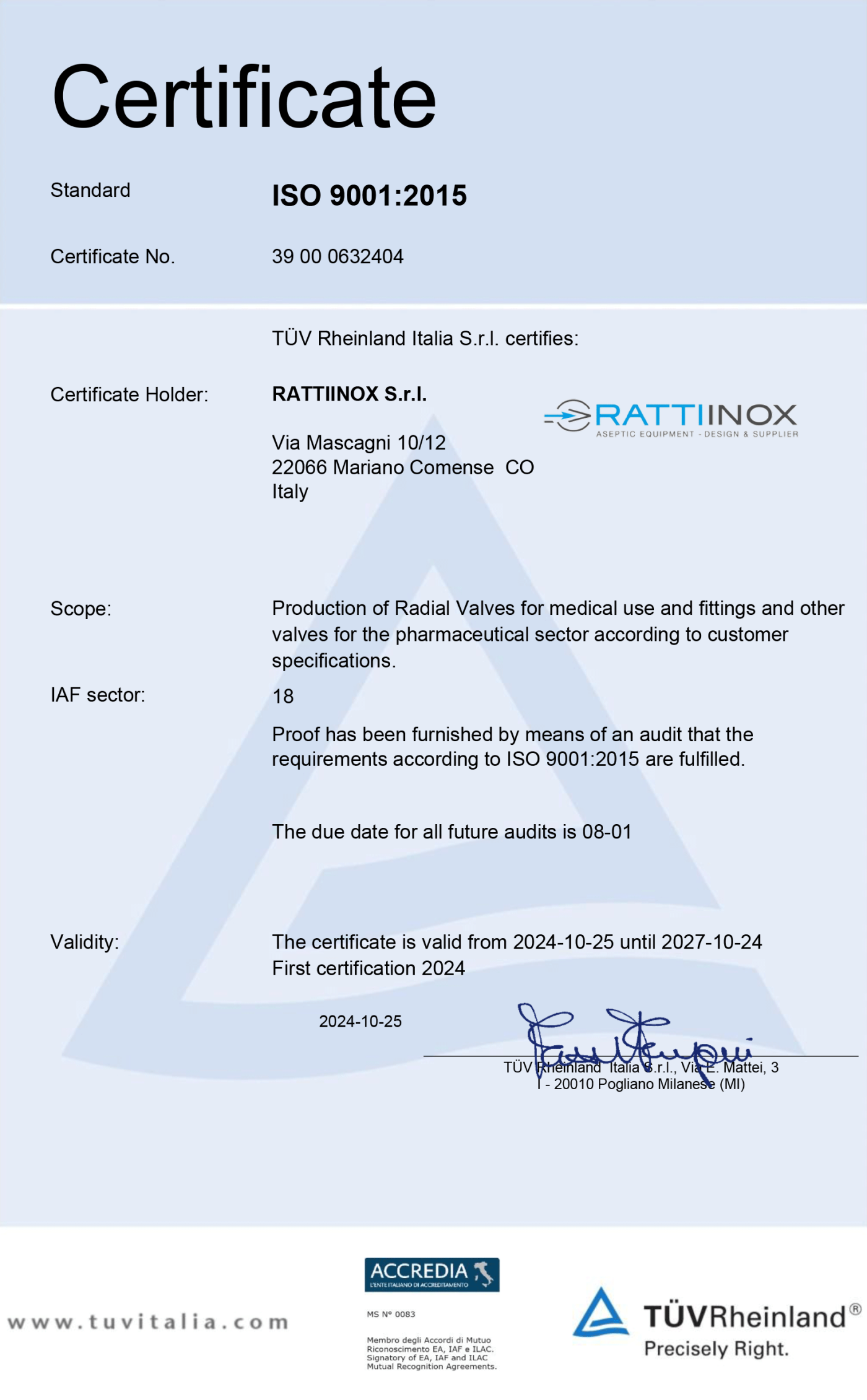

Rattiinox is certified

ISO 9001:2015